CNC AutoDoor designed a practical and robust housing for Sidoor. The control module is supplied ready-to-use with universal mounting brackets and a cable package so that it can be easily and quickly mounted on any CNC machine. The door opener is controlled by the I/O signals inside the machine or by pushbuttons that can be fitted optionally. Clients are enthusiastic about the ease of use, safety, professional look and integrity of this solution. „An unrivaled achievement,“ says Brad Woody, Upper Midwest Division President at Ellison Technologies. „The CNC AutoDoors have been a great success for us in retrofitting and after-sales activities. It’s a top-of-the-line industrial product that I can only recommend.“

98% less downtime

Engineer Bart van Halteren: „Our clients cannot afford machine downtimes due to malfunctioning doors. Especially pneumatic door openers regularly cause problems. Our solution with Sidoor works very reliably. As a result, clients have been able to reduce their downtimes by 98% compared to pneumatic door openers and are happy that they can purchase a complete door automation solution from a single supplier. The one-stop shopping formula saves time and money, partly because we can supply almost all models from stock.“

Efficient and less burdensome

The solution also provides an answer to the increasing scarcity of operators. As a consequence, operators face higher workloads. An automatic door opener contributes to safe and ergonomic working conditions. Van Halteren: „No company wants its employees to work in sub-optimal conditions. Operators who open and close heavy machine doors for eight hours a day are unnecessarily strained. By automating this task, there is less risk of physical complaints and more time for other tasks. This benefits their health and the company’s efficiency. In today’s market, metalworking companies must ensure 24/7 production, with a single operator controlling multiple machines. Every minute gained adds to the value of a CNC machine output.“

Reliability

HALTER CNC Automation, supplier of loading robots for CNC machine tools, used to purchase solutions for opening and closing machine doors from a different supplier. Robert van Soest, Product Specialist at HALTER CNC Automation: „We received little support and the delivery times were long. As a result, it wasn’t always possible to include the door opener in the delivery of our loading robot. Also, the quality was insufficient. Since 2017, we have been buying the automatic door openers from the Dutch company CNC AutoDoor. They developed a Plug&Play system based on Sidoor. We only use A brands. By choosing CNC AutoDoor with Sidoor, we can offer a reliable product.“

Continuous optimization

CNC AutoDoor designed the Sidoor housing with a digital CAD system, into which the 3D files of the Siemens components are read. Many product improvements have already been implemented since 2017. The number of components making up the housing has been reduced, which simplifies assembly. Van Halteren: „We continue to optimize and will also broaden our portfolio. Our current solutions are one to two meters long and suitable for single and double doors with a moveable weight of up to 180 and 400 kg. In time, we will also be supplying systems up to four meters long. These systems are suitable for doors with a moveable weight of up to 700 kg.“

Preventive maintenance

Sidoor can communicate via Profinet with a higher-level PLC for the entire automation system. This makes it possible to collect data and perform predictive maintenance. Industrial doors are critical components for safety and continuity, just like elevator doors or platform screen doors. Preventive maintenance increases availability and ensures flawless operation. The Profinet connection to the higher-level automation system is especially interesting for companies that have large machines with wide doors.

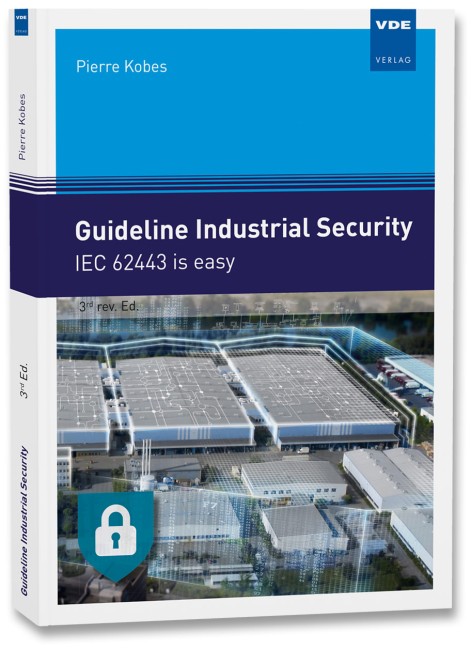

Industrial top-notch product

The Sidoor door control system consists of a drive motor and a controller. It has been used successfully in various environments for over 30 years. Elevator manufacturers use Sidoor for the automatic opening and closing of elevator doors. An application in the mobility sector is the control of platform screen doors at train stations in cities such as London and Beijing, preventing travelers from falling on the tracks. Sidoor can be commissioned quickly. There is no need to program it, instead it is only parameterized as needed. Safety is integrated in the controller. The system is safety-certified, automatically detects resistance, and thereby prevents unsafe situations. (Machinery Directive EN ISO14120, EN ISO13849 – 1 Performance Level d – Cat. 2)

New markets

Since 2017, CNC AutoDoor has sold increasingly higher numbers of door control systems every year. The product helps to meet the growing demand for retrofitting and single automation of CNC machines to enable robot loading. This solution is very suitable for quickly raising a machine’s productivity to a higher level and ensuring safety. No additional door sensors are needed. After installing the system onto the door and pressing the self-learning button, the door is ready to use. Van Halteren: „Our main markets are the United States, the United Kingdom, Germany, Scandinavia and Eastern Europe. In addition to machine tool vendors such as Mazak, Okuma, Hwacheon, Haas and many others, we also supply directly to end users in CNC metal processing, the automotive sector and industrial production. Now that we have a good grasp of the application for CNC machines, we are also keeping our eyes open for completely new markets which require automatic opening and closing of doors.“